- Home

- Products

- Manual Transmission

- Pressure Plates

- Details & Features

Details & Features

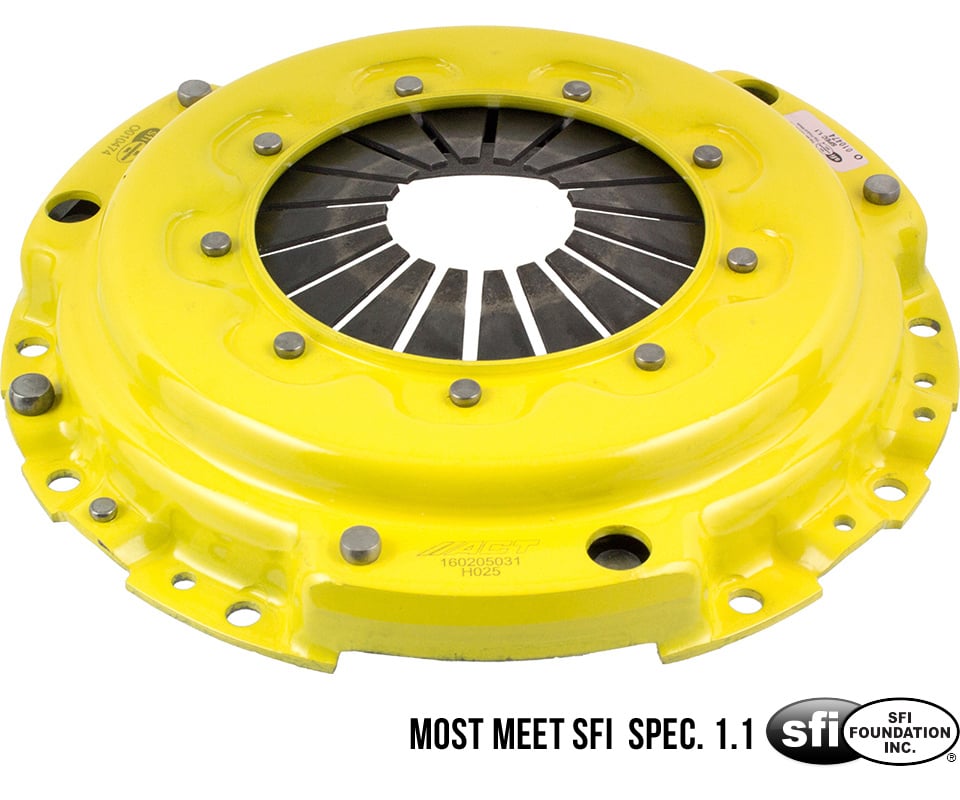

ACT Pressure Plates

All ACT pressure plate assemblies are newly manufactured units, not rebuilt from used parts. Many other clutch companies modify the original equipment (OE) pressure plate fulcrum slightly to produce limited benefits using the OE diaphragm spring. ACT fully engineers every application, designs and develops entirely new diaphragms and pressure plate faces. These steps are necessary to achieve vastly improved performance, well beyond the restrictions of the OE geometry.

Understanding ACT's Pressure Plates

100% TESTED

100 percent tested and computer balanced

SFI CERTIFIED

Most are SFI certified to ensure ACT parts exceed strict racing requirements

PRECISION STAMPED

Precision-stamped cover for maximum consistency and rigidity

INDUCTION HARDENED

Induction-hardened bearing contact area for extremely long wear life

DRIVE STRAPS & RIVETS

Drive straps and rivets securely locate contact face to the cover for quiet, trouble-free operation (no loose pieces to wear or rattle)

FOUR-STAGE HEAT TREATED

Exclusive four-stage, heat treating process performed on all diaphragms

ACT Pressure Plate Key Features

ALL FACTORY DESIGNS

ACT offers pressure plate assemblies for all factory designs: push-type, pull-type, crimp and rivet.

STIFFENING RIBS

Stiffening ribs are added to the diaphragm fingers, on select applications, to reduce pedal travel.

SFI 1.1 SPECIFICATION

Pressure plates noted as certified to SFI® Specification 1.1 are legal for competition in all racing organizations where such certification is required.

PROPRIETARY SINGLE DIAPHRAGM

Proprietary single-diaphragm designs are developed to dramatically increase clamp load without the drawbacks of double-diaphragm configurations.

REINFORCED COVER STAMPING

Many cover stampings receive reinforcements to reduce flex, and improve efficiency and pedal feel.

COMPUTER SPIN BALANCED

Every pressure plate is dynamically computer spin-balanced for smooth operation at any RPM.

STRONGER DRIVE STRAPS & HIGH GRADE RIVETS

Stronger drive straps and higher grade rivets are used, as required, to increase strength for higher torque and higher RPM applications.

CNC MACHINED FACE CASTINGS

All face castings are CNC-machined for maximum precision and greater consistency.

4 STAGE HEAT TREATED

Diaphragm springs are processed with an exclusive four-stage, heat-treating process for unparalleled performance, reduced deflection and maximum clamp load throughout the entire clutch life.

LOAD TESTED

Every pressure plate is load tested on a specially configured, computer-controlled testing press, as one part of the production quality assurance program.

ACT Pressure Plate Types